About Us

Truck Drive Shaft Universal Joint: The "Flexible Hub" for Power Transmission

Views : 55

Update time : 2025-07-15 10:23:21

In the power transmission system of a truck, the drive shaft universal joint is a seemingly small but crucial component. Although its structure is not complex, it plays a key role in the operation of the vehicle and is indispensable for ensuring stable power transmission and the normal operation of the vehicle.

I. What is a drive shaft universal joint?

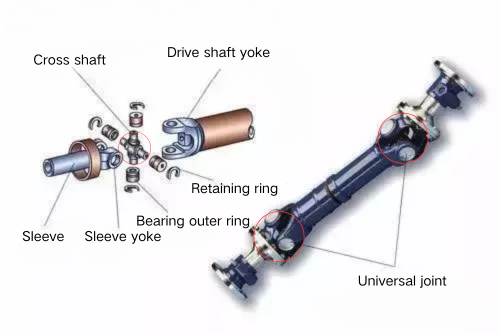

The drive shaft universal joint, also known as a universal joint, is a core component of the automobile drive shaft system. Its structure consists of a cross shaft, needle roller bearings, oil seals, journals, etc., and is overall cross-shaped. This design enables it to transmit power at different angles, allowing the two connected shafts to change their relative positions within a certain range while maintaining continuous power transmission, serving as a "bridge" for non-linear power transmission.

II. Where is the drive shaft universal joint installed?

The installation position of the drive shaft universal joint is closely related to the layout of the drive shaft, and it is usually located at:

- Both ends of the drive shaft;

- The connection between the drive shaft and the gearbox;

- The junction between the drive shaft and the drive axle.

Due to the long wheelbase of trucks, the drive shaft is often divided into multiple sections, and a universal joint is also installed at the connection between each two sections of the drive shaft. This distribution can adapt to the angle changes caused by the ups and downs of the truck body and steering during driving, ensuring that power transmission is not affected by the body posture.

III. What are the specific functions of the drive shaft universal joint?

1. Realizing angular power transmission

During the truck's travel, due to uneven road surfaces, steering, etc., the angle between the output shaft of the gearbox and the input shaft of the drive axle will constantly change. The drive shaft universal joint can flexibly adapt to this angle change, smoothly transmitting the engine's power from the gearbox to the drive axle, ensuring that the wheels continuously obtain driving force.

2. Buffering and shock absorption, protecting components

During power transmission, the operation of the engine and road bumps will generate impact forces and vibrations. Components such as the needle roller bearings in the universal joint can play a role in buffering and shock absorption, reducing the impact and vibration during power transmission, protecting the drive shaft and related components, and extending their service life.

3. Coordinating speed differences

When the drive shaft is running, the angular velocities of its two ends will vary with changes in the angle. The universal joint, through its structural characteristics, can coordinate this speed difference to a certain extent, making power transmission more stable and avoiding excessive power fluctuations that affect driving stability.

IV. How to determine the replacement cycle of the drive shaft universal joint?

The drive shaft universal joint has no fixed replacement cycle, and its service life is affected by many factors, which needs to be judged based on actual conditions:

1. Refer to the mileage traveled

Generally, when a truck has traveled more than 100,000 kilometers, it is recommended to focus on inspecting the universal joint. If signs of wear or looseness are found, it needs to be replaced in time; if it is in good condition, it can continue to be used with enhanced monitoring.

2. Pay attention to the usage environment

- Long-term driving on muddy, bumpy roads or frequent heavy-load transportation will accelerate the wear of the universal joint, and the replacement cycle may be shortened to within 80,000 kilometers;

- When the driving environment is flat and the load is light, the service life is relatively longer.

3. Attach importance to maintenance

Regular lubrication and maintenance are key to extending the service life of the universal joint. If lubricating grease is added in accordance with specifications (usually every 20,000-30,000 kilometers), component wear can be effectively reduced; if there is a long-term lack of lubrication, the needle roller bearings are prone to premature damage due to dry friction and need to be replaced as soon as possible.

4. Be alert to fault signals

When the universal joint has the following faults, it must be replaced immediately:

- Abnormal noises such as "clicking" or "clunking" during driving, especially when starting, accelerating, or turning;

- Obvious vibration of the drive shaft, which intensifies as the vehicle speed increases;

- Unsmooth power transmission and weak vehicle acceleration.

If these phenomena are not handled in time, they may cause the drive shaft to break, leading to serious traffic accidents.

Although the drive shaft universal joint is small, it is the "flexible hub" of the truck's power system. Mastering its structure, functions, and methods for judging replacement, and doing a good job in daily inspection and maintenance, can effectively ensure stable power transmission of the truck and guarantee driving safety.

相关新闻

Revealing Three Little-Known Facts About Trucks

Revealing Three Little-Known Facts About Trucks

Aug 06,2025

This article presents three little-known facts about trucks, including that the cab can be flipped for engine maintenance, the rearview mirrors are equipped with defrosting and deicing functions, and the small tank next to the fuel tank is an urea tank which is crucial for environmental protection. It helps readers understand the secrets behind truck designs and functions.

Control Valve: The "Key Steward" in Truck Engines

Control Valve: The "Key Steward" in Truck Engines

Aug 05,2025

This article introduces the role of the control valve in the diesel pump, including controlling fuel quantity and stabilizing pressure; lists symptoms when it malfunctions, such as weakened power and increased fuel consumption; provides maintenance methods, and illustrates through cases that paying attention to the control valve can avoid unnecessary expenses.

Control Valve: The "Invisible Commander" of Truck Power

Control Valve: The "Invisible Commander" of Truck Power

Aug 05,2025

The control valve is an indispensable core regulating component in the truck power system. Although it hides inside the machinery and keeps a low profile, it relies on its powerful functions to precisely command the rhythm of power output, comprehensively ensure driving safety, and intelligently adapt to various working conditions. With sophisticated design techniques and durable material selection, it can achieve a perfect balance between power and efficiency in various complex scenarios, and can be called the invisible cornerstone supporting the efficient and stable operation of trucks.

Truck Snow Chains: Safety Guarantee on Icy and Snowy Roads

Truck Snow Chains: Safety Guarantee on Icy and Snowy Roads

Jul 28,2025

This article elaborates on truck snow chains, including their important role on icy and snowy roads, applicable scenarios, selection methods, installation steps, and usage precautions. It aims to provide references for truck drivers to drive safely in icy and snowy weather and reduce accidents caused by slippery roads.